- Bahrain Steel

Bahrain Steel: Established in 1984, Bahrain Steel, wholly owned by Foulath, is a leading producer of iron-ore pellets used in the production of steel. It operates two pelletizing plants in the Kingdom of Bahrain with a total capacity of 12 million tons per year. It is the largest DR merchant pelletizing producer in the world and the only one located in the Middle East.

Bahrain Steel: Established in 1984, Bahrain Steel, wholly owned by Foulath, is a leading producer of iron-ore pellets used in the production of steel. It operates two pelletizing plants in the Kingdom of Bahrain with a total capacity of 12 million tons per year. It is the largest DR merchant pelletizing producer in the world and the only one located in the Middle East. - SULB

SULB Company B.S.C.:

SULB Company B.S.C.:

In 2009, Foulath formed SULB as a joint venture with the Japanese steel industry Yamato Kogyo and opened its DRI and heavy steel production plant in Bahrain. It acquired a light-to-medium rolling mill in Jubail, which became SULB Saudi Arabia. The two parts of SULB meet the region’s needs for steel sections, with exports made further afield. It is the Middle East region's first fully integrated medium and heavy beams and structural steel sections producer. - Foulath Infotech

Foulath Infotech: In 2019, Bahrain Steel and its sister companies from the Foulath Group engaged in an all-out commitment to a state-of-the-art digitalization transformation programme. Welcome to the start of a new era. Welcome to Foulath 4.0

Foulath Infotech: In 2019, Bahrain Steel and its sister companies from the Foulath Group engaged in an all-out commitment to a state-of-the-art digitalization transformation programme. Welcome to the start of a new era. Welcome to Foulath 4.0

| Bahrain Steel |

|

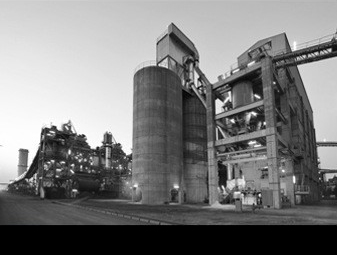

Bahrain Steel (formerly GIIC), a wholly owned subsidiary of Foulath was established in the Kingdom of Bahrain in 1984. Located on the Foulath Complex in the Hidd Industrial Area, Bahrain Steel operates two iron ore pelletizing plants with a total production capacity of 11.0 mtpy. Over time, Bahrain Steel has established its reputation as a market leader and is only one of three merchant pelletizing plants in the world and the only such operator in the Middle East region. The Company invests considerably in maintaining its reputation in the iron and steel industry as a top quality producer of iron oxide pellets and is committed to providing its customers with the quality of products and services that meets their needs and exceeds their expectations. Bahrain Steel produces mainly Direct Reduction (DR) - grade pellets for its customers in the Middle East, India, Far East and South East Asia. Blast Furnace (BF) – grade pellet production is also utilised from time to time when manufacturing pellets for customers in India, China and Japan. Bahrain Steel provides high quality iron oxide pellets to its customers in line with agreed specifications and delivery schedules whilst putting customer satisfaction as its topmost priority. Bahrain Steel is distinguished by the following competitive advantages in the production of its quality pellets:

To ensure the Company continues uninterrupted production of its market leading pellets, Bahrain Steel has secured its high-quality iron ore requirements for its plants from the most reliable and reputable iron ore suppliers through long-term (up to 25 years) contracts. Bahrain Steel has operated an integrated management system since 2003 that meets the requirements of ISO 9001:2008 and ISO 14001:2004. This enables the Company to comply with national and international laws and regulations that apply to various aspects of its operations. In particular, GIIC is committed to environmental protection and ensuring it minimizes the impact of its activities on the environment and prevents pollution in the most effective manner. Today Bahrain Steel employs approximately 450 people of whom 70% are Bahraini nationals. Aware that its employees are the most valuable assets of the Company, Bahrain Steel’s Management places great emphasis on the training and development of its staff and to adopting policies that foster employee satisfaction and promote team spirit within the Company. |